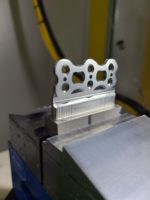

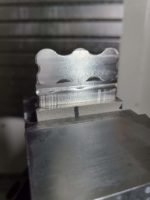

April 28, 2021 – Our Mastercam team hosted their second episode of Knowledge on Tap which showcases features from both the software and machine tool side. In Episode Two, our team showcased 5-Axis Accelerated Finishing on complex titanium bone plate.

Unified Multi-Axis for Mastercam2022

As we hinted in our last episode, our team would be programming in Mastercam2022 which is set to release June 1st of this year. Stay tuned for roll-out information!

Unified Multi-Axis is a combination of parallel to curve, parallel to surfaces, morph tool path between curves and surfaces as well as Flowline. The combination of the toolpaths gives you different tool strategies you can take based on the geometry you take.

Click on the video below for a slightly deeper dive in Mastercam2022 BETA.

Mastercam Tech Exchange

In this episode, Brandon was able to pull the tool files for EMUGE from the Tech Exchange. If you haven’t heard of this, the Tech Exchange is a page on the Mastercam website here you can download files for tooling to use in your projects. Some examples of what is available for download include tool libraries, posts and sample files. Contact our Mastercam team today to learn more!

Thank you Sponsors

- All holders are balanced to G 2.5 specifications

- BT holders are offered in 3 designs (A, B, C)

- ISO taper shank acc. DIN ISO 7388-2

- Internal coolant supply

- FPC collets and accessories order separately

- Slim line versions offer a 4.5° tapered neck for extra clearance

Interested in more information? Click here.

FMC collets are used in conjunction with FMC extensions to provide additional tool reach. The FMC collet screws into the FMC collet extension (Parts Listing). The collet extension is then seated within the standard FPC collet & holder. The FMC collet will fit into all FMC extensions. Match the FMC collet ID with the cutting tool shank diameter.

Interested in more information? Click here.

Solid Carbide Circle Segment end mills with Taper Form A that can simulate a 50 to 1,000 mm radius cutter

- Low vibration machining

- Flute form tolerance = ±0.01 mm

- Suitable for most materials

- ALCR multi-layer PVD coating for heat and wear resistance

- Form A: allows up to 45˚ tilt angle

Interested in more information? Click here.

Solid Carbide Circle Segment end mills with Oval Form that simulates a 50 to 95 mm radius cutter

- Low vibration machining

- 3, 4 & 6 flute construction

- Flute form tolerance = ±0.01 mm

- Suitable for all most all materials

- Roughing (3552LZ.) & finishing design options

- Solid and coolant fed designs are available

- ALCR multi-layer PVD coating for heat and wear resistance

Interested in more information? Click here.

Top-Cut VAR tools are a versatile and economical variable helix carbide end mill design for universal applications.

- Variable helix flute construction for vibration dampening

- Sub-micro grain carbide

- ALCR coating for heat and wear resistance

- Chamfer corner break extends tool life

- HB / Weldon flats available

Interested in more information? Click here.

The Trochoidal TiNox-Cut series was especially developed for use with advanced milling strategies in machining titanium alloys, nickel based alloys and stainless steel.

- Vibration dampening with variable helix/flute spacing

- Heat and wear resistant multi-layer TIN/TiAlN – PVD applied coating

- Roughing/finishing flute profile for optimum performance

- Staggered chip breaker design for even wear in depths up to 4xD

- Coolant fed (axial) design for efficient chip evacuation

- HB / Weldon flats

Interested in more information? Click here.

Emuge EF-Series 3xD length is available coolant fed double margin or solid with a single margin design. Each version is available with and without a shank flat.

- Advanced sub-micro grain carbide substrate

- Single margin design

- Four facet – 140˚ point angle

- Cut diameter – m7 flute tolerance range

- TIALN-T14 multi-layer PVD hard coating for heat and wear resistance

- Unique core web construction allows for maximum chip evacuation rates

- HA style cylindrical shank DIN 6535

- Shank diameter – h6 shank tolerance range

Interested in more information? Click here.

Emuge EF-Micro drill is designed to run fatster and longer than conventional carbide micro drills.

- Specialized point geometry generates short chips and guarentees optimum performance

- Rolled heel flute design for maximum chip evacuation

- Multi-Layer TiALN-T99 PVD coating for heat and wear resistance

- Single channel intake bore for maximum coolant flow

Interested in more information? Click here.

Top-Cut VAR ball nose end mills are a versatile variable helix carbide end mill design for universal applications.

- 35/38˚ variable helix design for vibration dampening

- Center cutting end design

- ALCR coating for heat and wear resistance

- HA cylindrical shank

- Universal material applications

Interested in more information? Click here.

Machining in Action

Want to learn more about Mastercam and our Machine Tool Showroom? Looking to make an upgrade in software? Our team of applications and engineers and sales engineers are ready to answer any questions you have.

Contact our team today!