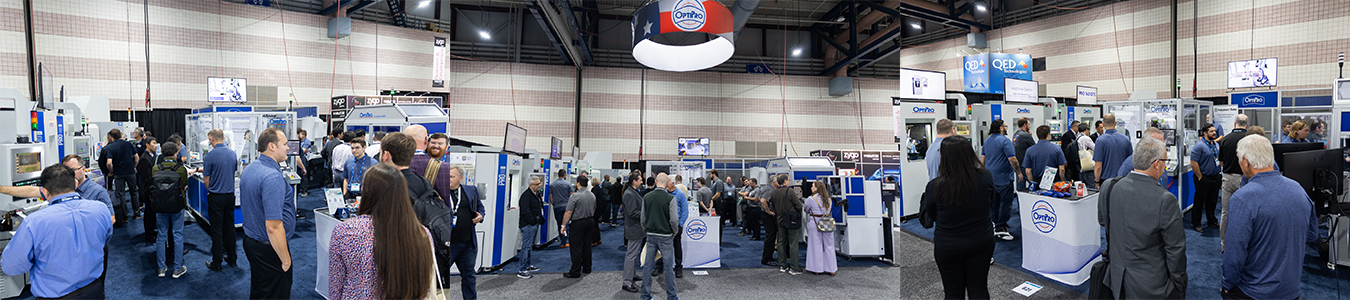

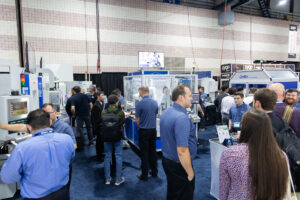

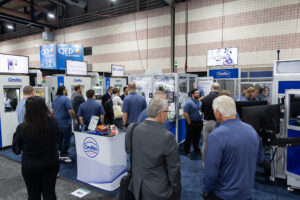

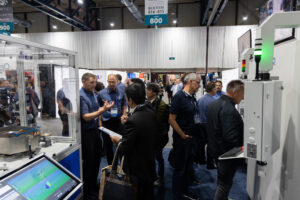

It was an action-packed week at SPIE Optifab! OptiPro’s booth featured eight machine demonstrations, including the Revel™ robotic beveling machine and the debut of a new non-contact asphere metrology machine. In addition, OptiPro presented three technical talks on the latest technological advancements to help companies make their manufacturing process more efficient.

The latest technology for manufacturing spheres, aspheres, freeforms optics and more.

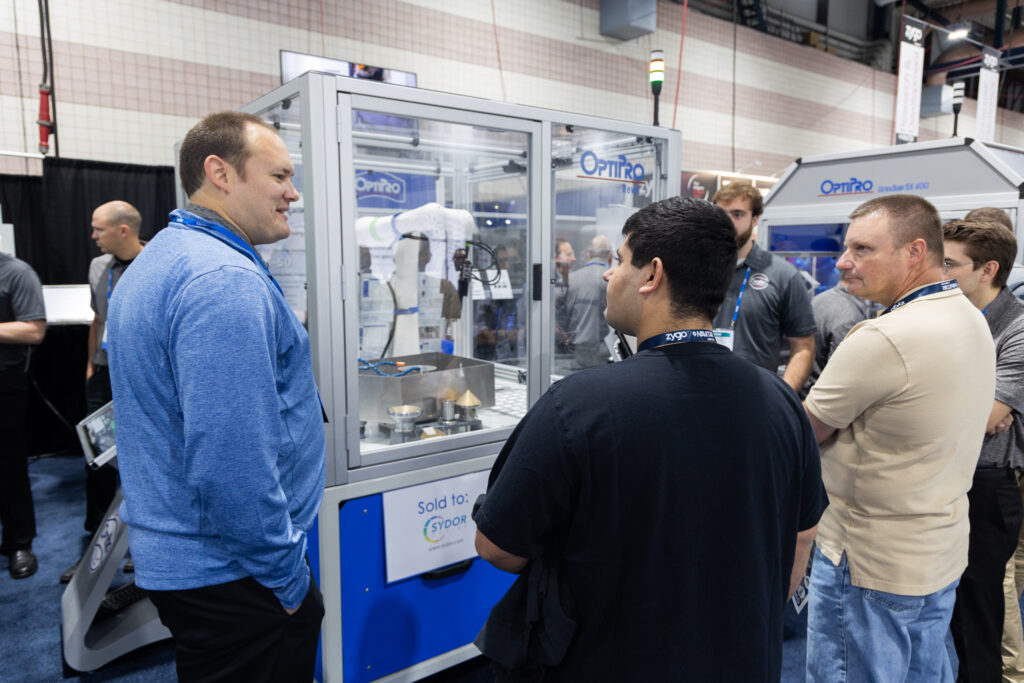

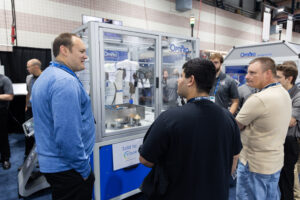

The Revel™ robotic beveling machine took center stage in OptiPro’s booth. This machine, which launched in early 2023, demonstrated the capability of fully-automated beveling of round optical blanks. The Revel™ frees technicians from performing the tedious task of beveling optics and can operate lights-out, keeping productivity high even after hours.

OptiPro also soft-launched a new compact non-contact asphere metrology system, which is a smaller version of OptiPro’s current UltraSurf machine. Ideal for precision aspheres up to 100mm, this machine was featured prominently in the front of the booth and garnered a lot of attention throughout the show.

OptiPro’s UltraSurf 5X 400 was placed in the booth next to the smaller version, and demonstrated 5-axis metrology of a polished freeform optical surface. With the UltraSurf 5X 400, user-friendly software and a simple three-step process makes it easy to set up measurement jobs involving complex freeform surfaces.

A machine demo of multi-axis light-weighting and beveling ran on the OptiSonic 550X ultrasonic machining center. OptiSonic technology allows companies to rapidly remove material with minimal tool wear, ideal for such applications as light-weighting mirrors.

Attendees interested in aspheric optics production were able to see asphere grinding and polishing on the PRO 160 GTS and PRO 80 UFF, respectively. PRO 80/PRO 160 machines are ideal for companies in need of a reliable asphere manufacturing cell.

High speed spherical optics polishing of meniscus lens on the PRO 160P+ showed the capability of this machine to handle large volume production jobs.

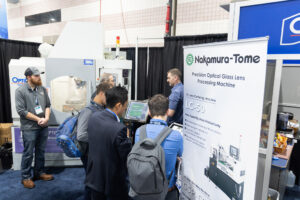

OptiPro also welcomed a representative from Nakamura-Tome to their booth staff, who assisted with answering questions from attendees regarding the Nakamura-Tome LC-50 centering machine.

Last, but not least, the ZEISS O-Inspect 322 performed fast, accurate, multisensor measurement of intricate & delicate glass workpieces. Thin walls and sharp edges are no problem for the ZEISS O-Inspect 322, which enables you to optimally measure each characteristic with tactile and optical sensors.

Automation, freeform optics, and OptiSonic the focus of three technical presentations

During the Optifab Conference, OptiPro shared their latest advancements in freeform optics manufacturing, automation, and OptiSonic grinding:

Frank Wolfs, Senior Algorithm Engineer, gave a technical presentation on: “Advances in Freeform Manufacturing“. Frank went into detail about the requirements that need to be met in order to successfully develop a manufacturing process for freeform optics.

Mitch Sedore, Head Automation Engineer, presented on the topic “Automation in Optical Manufacturing: Beveling and Part Handling“. Mitch explains how OptiPro automation solutions help customers increase productivity while reducing labor cost.

In addition, Mike Cahill, Mechanical Engineer, shared a presentation on “Ultrasonic Machining of Optical and Ceramic Materials“. In his talk, Mike discusses how OptiSonic technology overcomes the challenges associated with machining glass and ceramics.

We want to thank everyone who stopped by OptiPro’s booth at SPIE Optifab!

If you missed Optifab this year or want to relive your OptiPro booth experience, check out photos from the event below:

If you are in the market for a solution that can take your optics or ceramics manufacturing to the next level, we encourage you to reach out to us. Whether you are looking enhance production of planos, spheres, aspheres, or freeform optics, OptiPro has the perfect machine for your application.