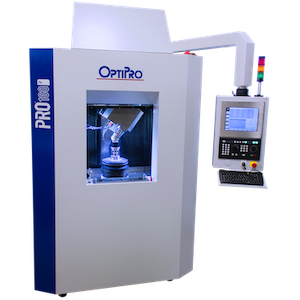

PRO 160P CNC Spherical Lens Polisher: Optics up to 160 mm

-

Overview

PRO 160P Overview

The PRO 160P CNC spherical lens polisher is capable of high speed polishing of spheres up to 160 mm in diameter. The PRO 160P features a vibration isolated granite base for ultimate precision, thermal stability, and consistent part-to-part accuracy. This compact, modular platform has double the part size capability as the PRO 80P while having only a slightly larger footprint. Driven by user-friendly software for high speed polishing (P Series), fast setups and cycle times are achieved with the PRO 160P allowing companies to produce precision spherical lenses in high volumes.

Multiple advanced features on the PRO 160P help companies increase quality and throughput of spherical optics:

- Precision polishing: Stiff granite machine base to reduce vibrations

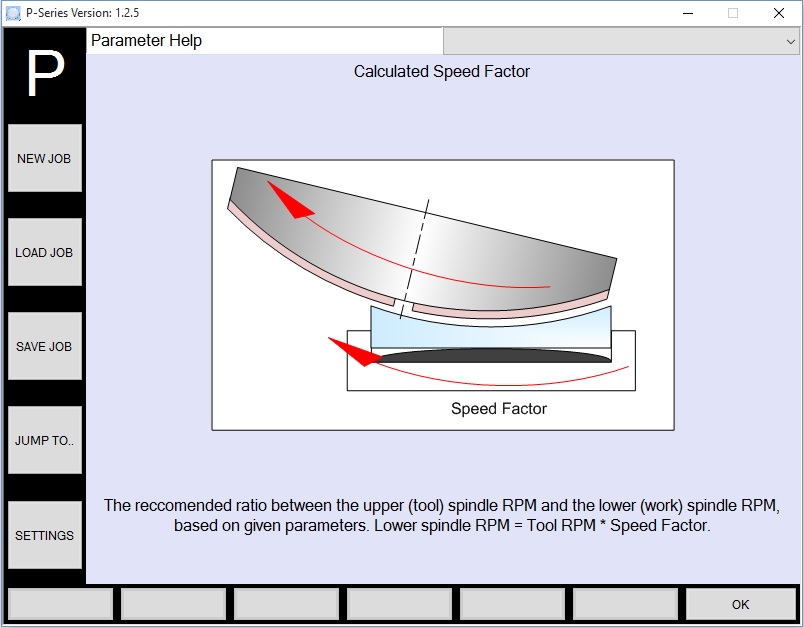

- Faster set ups: Easy-to-learn P Series software with the ability to chain multiple process cycles together

- User-friendly interface: Simple input handles and graphics guide the user through all aspects of lens polishing

- Versatility: High speed polishing of convex and concave lenses, as well as spherical domes

- Extensive material processing: Polish different optical materials to angstrom-level quality by utilizing a variety of polishing pad and slurry combinations

- Ergonomically designed: Helps machine operators maximize productivity

- Energy efficient: Servos turn off automatically

- Easy cleanup for fast slurry changeover: All stainless steel containment makes it easy to clean, saving time and money when switching from one job to another

- Convenience and confidence: Polishing tool correction and truing can be programmed and performed in radius, sag and fringes directly on the polisher, saving time during job setup and ensuring desired polishing results

- Tooling flexibility: Available with optional UltraSmooth Finishing (USF) capability for polishing aspheres

Achieve high volume production of precision spherical optics with the dependable and efficient PRO 160P high speed polisher.

-

Specs

PRO 160P Technical Specifications

High Speed Polishing Machine Specifications* PRO 80P PRO 160P/PRO 160P+ ePX 200 Workpiece Optimal Diameter Range Up to 80 mm (3.15") Up to 160 mm (6.3") Up to 200 mm (7.87") Maximum Weight 15 kg (33 lbs.) 30 kg (66 lbs.) 100 kg (220 lbs.) Work Spindle** Spindle Speed, Power 1-1,500 RPM, 1.3 kW 1-1,500 RPM, 1.8 kW 25-2,000 RPM, 5kW Hydro-Expansion Chuck Standard Standard Standard Work Chuck Pneumatic Bladder Pneumatic Bladder Pneumatic Bladder Tool Spindle Maximum Tool Diameter 160 mm (6.3") 300 mm (11.8") 400 mm (15.7") Spindle Speed, Power 50-1,500 rpm, 1.3kW 0-1,500 rpm, 1.8kW 25-2,000 rpm, 5kW Hydro-Expansion Chuck Standard Standard Standard Polishing Tool Aluminum or Steel Body with Polyurethane Foil Aluminum or Steel Body with Polyurethane Foil Aluminum or Steel Body with Polyurethane Foil Travels X-Axis Travel 170 mm (6.7") 420 mm (16.5") 468 mm (18.4") Y-Axis Travel 3 mm (0.12") 6 mm (0.24") 210 mm (8.3") Z-Axis Travel 140 mm (5.5") 220 mm (8.6") 200 mm (7.87") B-Axis Travel -5° to 65° -5° to 65° -90° to 90° Communication Interface Ethernet Standard Standard Standard USB Standard Standard Standard Machine Dimensions Width 1,000 mm (39") 1,400 mm (55") 2,110 mm (83") Depth 1,500 mm (59") 1,730 mm (68") 2,515 mm (99") Height 2,440 mm (96") 2,440 mm (96") 2,700 mm (106") Weight 1600 kg (3,500 lbs.) 1950 kg (4,300 lbs.) 3,400 kg (7,500 lbs.) Electrical 480V +/- 5%, 24A 480V +/- 10%, 24A 480 V +/- 5%, 49A Compressed Air 100 PSI, 5 CFM clean dry air 100 PSI, 5 CFM clean dry air 100 PSI, 5 CFM clean dry air Coolant Water DI Water DI Water DI Water * Specifications subject to change. Contact OptiPro for the latest specifications.

** PRO 160P+ has dual lower spindles (Work Spindle and Truing Spindle), both of which have the same specifications.Machine Features

- 4 controllable axes: X, Y, Z, & B

- Fagor 8065 CNC machine control with a high resolution LCD touch screen monitor and simplified user interface

- Menu-driven data entry screens with operator prompts for process data input minimizes set-up time

- User can define multiple process steps for each job

- Easily accessible work area for hemisphere fixtures

- Continuous display of cycle time and spindle load meters

- Polishing tool correction and truing directly on the polisher

- Quick set-up and process change-over

- Polishing slurry system

Optional Equipment

- Tool Height Measurement Station

- Slurry Through the Tool

- Tooling Packages

- Tool design program for tool and chuck selection

-

Video